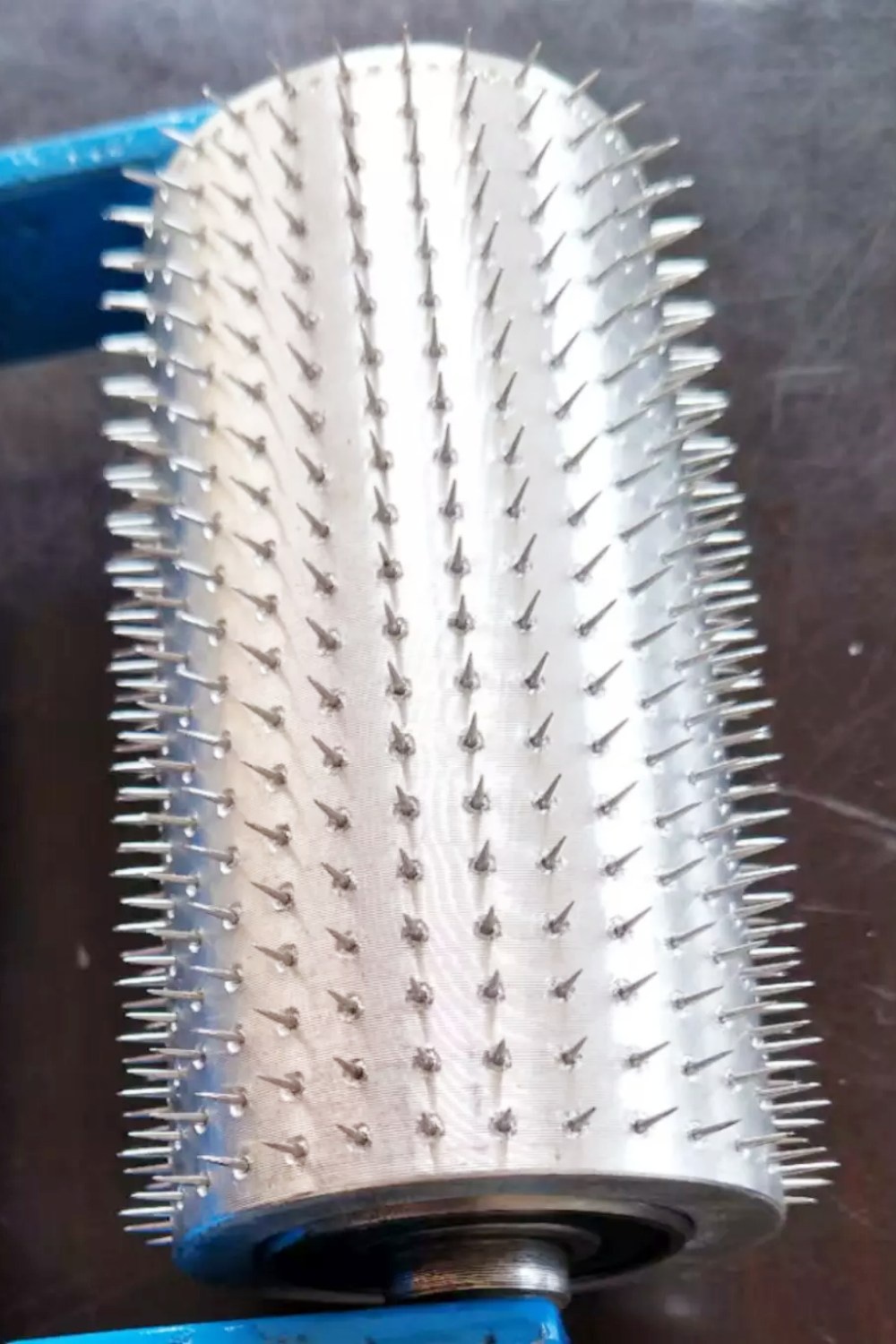

Rodillo de cepillo de alambre abrasivo industrial personalizado para tratamiento de superficies

Diseñado para brindar precisión y durabilidad, este rodillo de cepillo de alambre abrasivo Es ideal para aplicaciones de tratamiento de superficies como desbarbado, limpieza y eliminación de óxido. Sus cerdas densas y uniformemente distribuidas proporcionan un rendimiento abrasivo constante, lo que lo hace perfecto para líneas de procesamiento de alta velocidad en las industrias metalúrgica y manufacturera.

Fabricado con alambre de grado industrial y un eje central robusto, este rodillo de cepillo garantiza una larga vida útil en condiciones exigentes. Ya sea para eliminar capas de óxido o preparar superficies para recubrimientos, ofrece resultados fiables y uniformes en diversos materiales, como acero, aluminio y compuestos.

El rodillo cuenta con filamentos abrasivos compactados que mantienen su forma y eficacia incluso después de un uso prolongado. Su diseño equilibrado minimiza la vibración, mejorando la estabilidad operativa y protegiendo el equipo de procesamiento del desgaste.

Características

- Fabricado con alambre abrasivo de alta densidad, este rodillo garantiza un tratamiento de superficie uniforme y un rendimiento duradero.

- Su robusta estructura central, fabricada en acero inoxidable o acero al carbono, está diseñada para aplicaciones industriales de servicio pesado.

- El diseño equilibrado con precisión minimiza la vibración, lo que garantiza un funcionamiento suave incluso a altas velocidades.

- Con especificaciones personalizables como longitud, diámetro, tipo de alambre y tamaño de grano, se puede adaptar para satisfacer necesidades específicas.

- Los materiales resistentes a la corrosión y al desgaste lo hacen adecuado para entornos hostiles, mientras que su distribución uniforme de cerdas garantiza un contacto uniforme con la superficie y un tiempo de inactividad mínimo, lo que lo convierte en una opción ideal para sistemas automatizados.

Ventajas

- Durabilidad y longevidad: fabricado con materiales de alta calidad, este rodillo de cepillo de alambre está diseñado para soportar un uso prolongado en entornos industriales hostiles, ofreciendo un rendimiento duradero.

- Resultados consistentes y eficientes: Los alambres abrasivos distribuidos uniformemente garantizan una abrasión uniforme, brindando resultados consistentes de limpieza, desbarbado y pulido en todo momento.

- Calidad de superficie mejorada: ideal para lograr superficies lisas, pulidas y libres de contaminantes, lo que lo hace perfecto para procesos de pre-recubrimiento y acabado.

- Costos de Mantenimiento Reducidos: Su diseño robusto reduce el desgaste de la maquinaria, minimizando los tiempos de parada y bajando los gastos de mantenimiento.

- Amplia aplicabilidad: adecuado para su uso en una variedad de industrias, incluidas la automotriz, la metalurgia y la fabricación, para una variedad de tareas de tratamiento de superficies.

Clasificación de productos

1. Según el material, las ruedas de pulido se dividen en ruedas de alambre de cobre, ruedas de alambre de cobre para recubrimiento, ruedas de alambre de acero inoxidable y ruedas de alambre galvanizado. Si el material no es muy transparente, todas se denominan ruedas de alambre.

2. La rueda de pulido según el proceso se dividirá en A, B, T, cepillo de pluma, tipo plano, tambor de eje largo, cepillo de tubería, cuenco y otras formas especiales no estándar.

Solicitud

Rodillo de cepillo de alambre abrasivo industrial Se utiliza para rectificar y pulir placas de acero, rectificar soldaduras, cepillar pisos de madera, rectificar placas de aluminio, etc. Los productos son ampliamente utilizados en neumáticos nuevos, construcción naval, industria de fabricación de maquinaria, maquinaria alimentaria, fabricación de equipos químicos, industria petrolera y de la construcción, industria aeroespacial, fabricación de automóviles, pulido de superficies de metales no ferrosos, máquinas pulidoras, industria del caucho, industria metalúrgica, fabricación de baterías, máquinas peladoras de cables, pulido de orificios internos de tuberías y otras industrias.

Se utiliza específicamente para pulir, esmerilar y eliminar óxido de acero inoxidable, que presenta requisitos especiales para los materiales de los artefactos en diversas industrias. Los materiales específicos para acero inoxidable son: 201, 202, 301, 304, 316, 316L (solo para acero inoxidable 304/316).

Español

Español English

English Français

Français Deutsch

Deutsch عربي

عربي

Network Supported

Network Supported